Material Specifications for Shoulder Washer

- Material: Spring Steel

- Material Grade: Stainless Steel, Copper, Brass

- Surface Finish: Zinc Plated

- Shape Options: Square, Round, Spring

- Size: Customizable as per client request

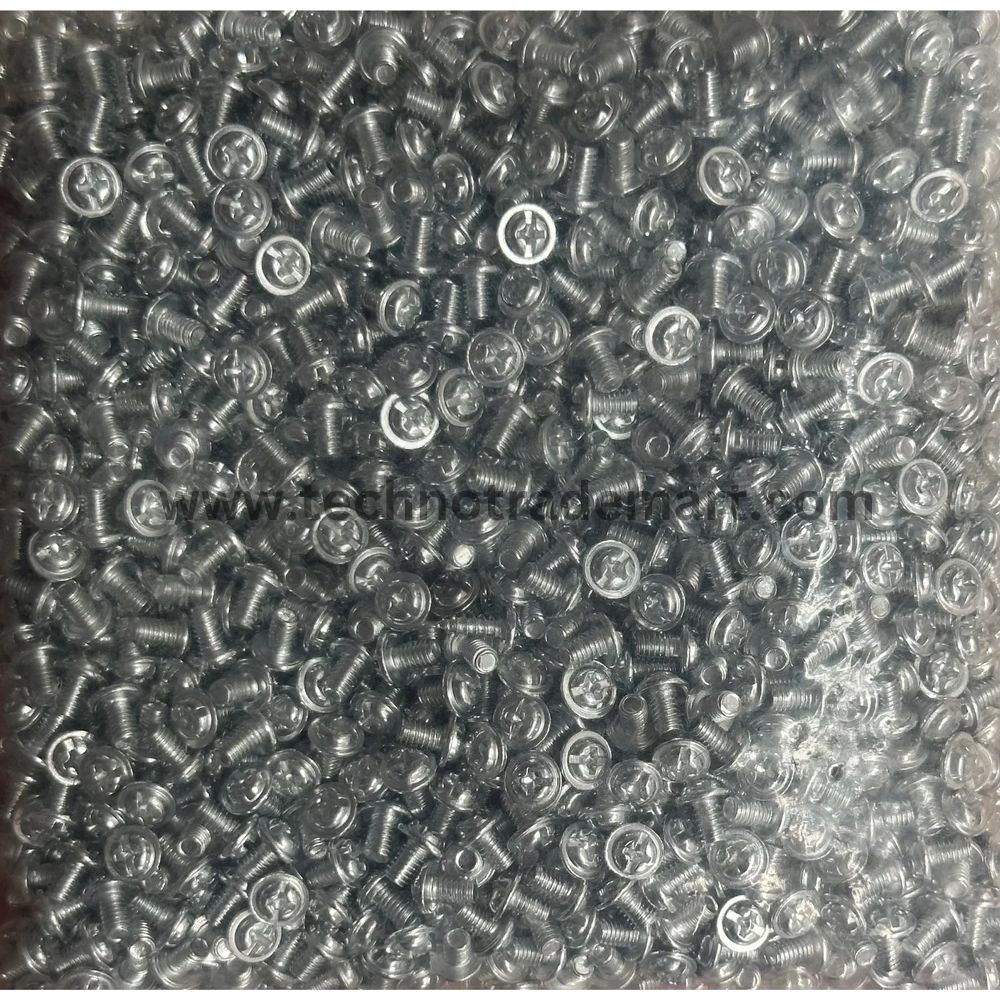

Packaging Details

- Types:

- Carton

- Jute Bag

- Packet

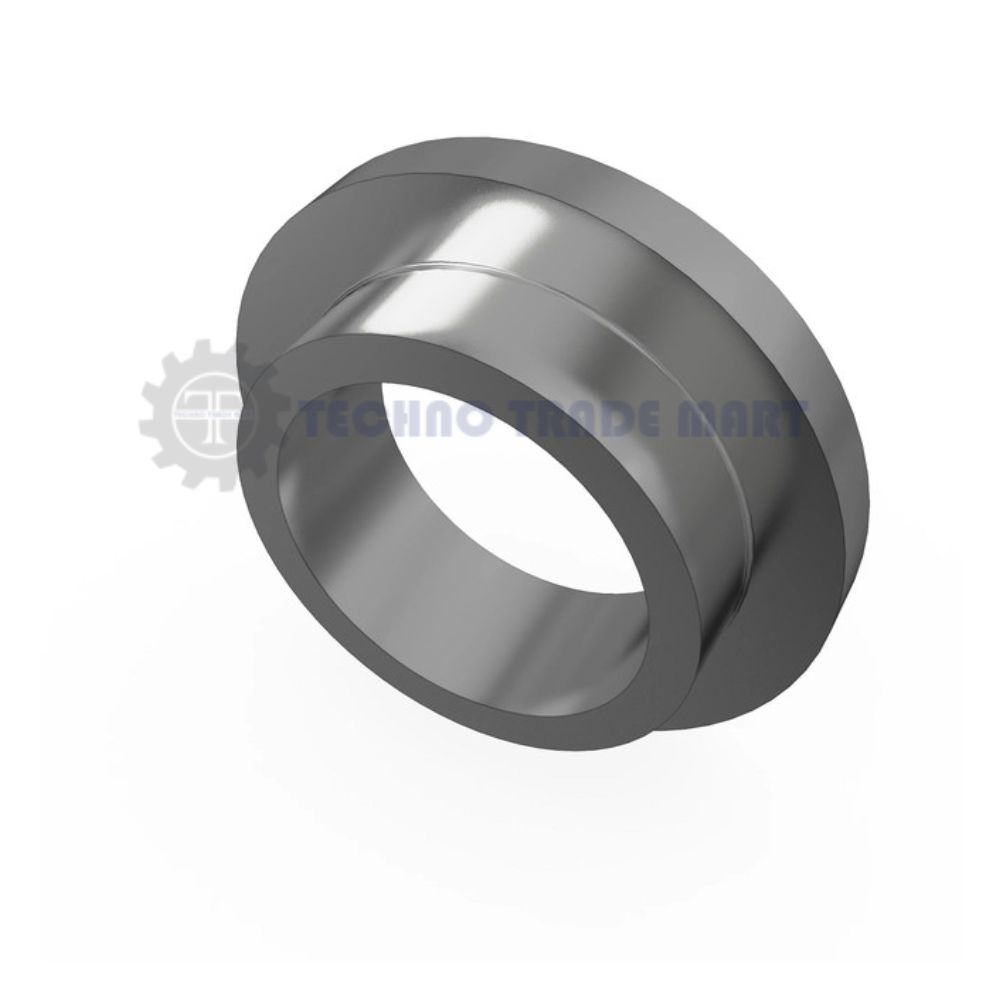

Description of Shoulder Washer

A Shoulder Washer, also known as an insulating washer or sleeve washer, is a specialized type of washer with an extended cylindrical sleeve or shoulder that provides additional support or insulation. It is commonly used in applications where electrical insulation, spacing, or mechanical support is required. These washers prevent direct contact between fasteners and components, reducing the risk of electrical short circuits or wear.

Technical Specifications

- Material:

- Nylon

- Polycarbonate

- PTFE (Teflon)

- Phenolic Resin

- Brass (for specific applications)

- Dimensions:

- Inner diameter: 1 mm to 25 mm

- Outer diameter: 3 mm to 50 mm

- Shoulder height: Customizable based on application

- Wall Thickness: Standard or tailored for precise insulation.

- Temperature Resistance:

- -40°C to 150°C for plastics (varies by material).

- Up to 260°C for high-performance materials like PTFE.

- Electrical Properties:

- Dielectric strength: 500-800 volts/mil (varies by material).

- Compliance Standards:

- RoHS

- UL94 for flammability

Features

- Electrical Insulation: Prevents electrical contact between fasteners and conductive surfaces.

- Cylindrical Shoulder: Provides mechanical support and precise spacing.

- Durable Materials: Made from resilient materials like nylon or PTFE for longevity.

- Corrosion Resistance: Non-metallic materials resist rust and degradation.

- Wide Temperature Range: Suitable for both low and high-temperature environments.

- Lightweight Design: Adds minimal weight to assemblies.

- Customizable Dimensions: Tailored for specific engineering requirements.

Uses

- Electronics: Provides insulation between screws and PCB components to avoid short circuits.

- Automotive Industry: Used in wiring harnesses and assemblies requiring electrical insulation.

- Aerospace: Ensures secure and insulated fastenings in critical applications.

- Appliances: Prevents electrical contact between parts in home and industrial equipment.

- Machinery: Used in moving parts to provide spacing and reduce wear.

- Construction: Provides mechanical support and insulation in building systems.

- DIY Projects: Useful for creating insulated or spaced joints in hobbyist projects.

| Additional features | |

|---|---|

| Value 1 | 21 cm |

| Value 2 | 700 gr. |

| Value 3 | 10 person |

| Value 4 | 14 cm |

| Value 5 | plastic |

.jpg)

.jpg)

.jpg)

.jpg)